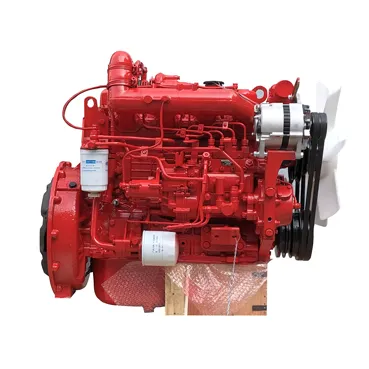

Advanced design and sophisticated manufacturing, adapt to a variety of harsh working conditions, high-intensity, heavy-duty work ability.

Cylinder block and cylinder head adopt integrated design to prevent the occurrence of engine water and oil leakage. The parts are about 40% less than other similar engines, and the failure rate is greatly reduced.

The cylinder bore adopts a platform mesh honing design, the perfect geometric structure effectively prevents oil leakage, and adopts advanced technologies such as new piston ring components and gasket crimping molding to reduce oil loss.

Adopt Holset supercharger with integral wastegate valve, low speed response and strong power.

The three-stage fuel filter ensures a balanced level of particle dispersion, protects the main components of the fuel system, and maximizes the life of the engine.

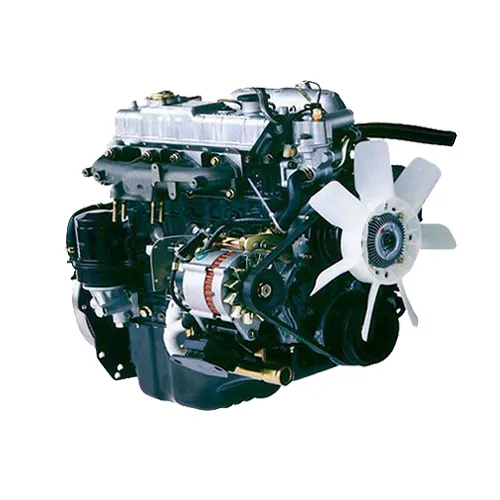

The 6BD1 engine featured an inline, six-cylinder design.

The pistons had a total displacement of 5,785 cc.

The maximum power output measured 142 horsepower at 2,800 rpm, and the total torque output measured 289 foot-pounds at 1,600 rpm.

The bore by stroke measured 4.02 by 4.63 inches, and the compression ratio measured 17.5:1. The engine utilized a 12 V starter and the cooling system used a liquid-cooled design.

The fuel system featured direct injection technology, and the valve-train used an overhead valve layout.